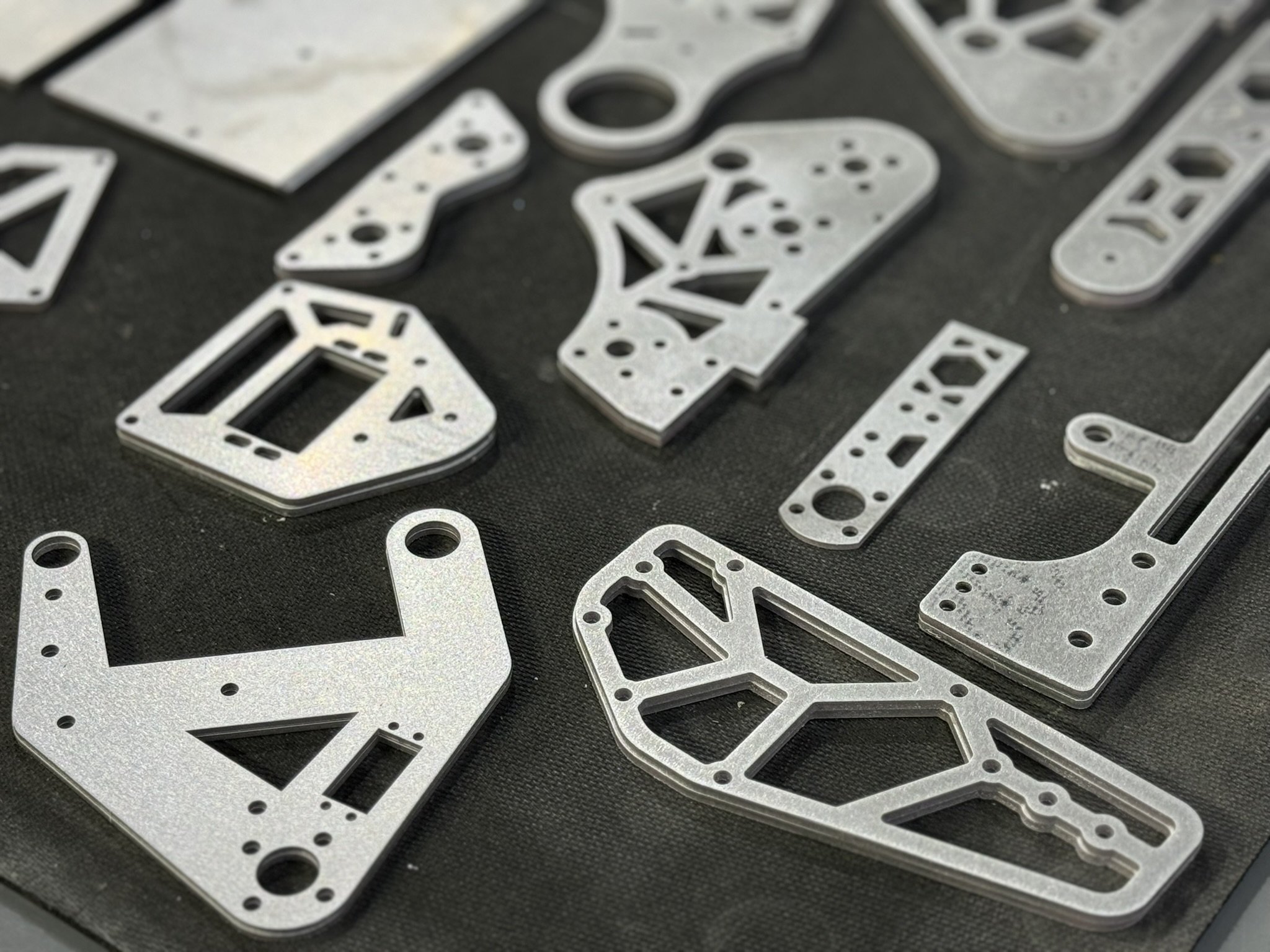

LASER CUTTING SERVICES

Parts need to be at least 0.150" apart from each other, and there should be a 0.500" border around the sheet for clamping it to the Laser table. Thicker materials may require more space between parts. Laser cutting makes the edges sharp and the cut areas shiny with lines, which can change depending on the material and gas used.

Laser Cutting will cut Aluminum, Stainless, Nickel Alloys, Titanium & Steel.up to 0.187” thick, Steel up to 0.625” thick & Stainless up to 0.250” thick.

Heat is generated on the cutting process

Minimum thickness = 0.005” thick

Maximum thickness = 0.625” thick

Minimum part size = 0.500” x 0.500”

Maximum part size = 59.50” x 119.50”

Hole Sizes = Minimum hole size is based on the thickness of the material being cut. Its typically a one to one proportion. For example, a 0.125” thick material requires a minimum hole size of 0.125”

Typical tolerances:

Holes +/-0.005”

Hole Location +/-0.005”

Profile +/-0.010”

Still unsure or need help with a quote? Send us an email anytime at Quotes@acpwaterjet.com

🔎 Frequently Asked Questions (FAQ)

Q: What materials can you laser cut?

We laser cut steel, stainless steel, aluminum (up to 1.00" thick), and approved plastics like acrylic, Delrin, and Teflon within specified thicknesses.

Q: What’s the max thickness you can laser cut?

Up to 1.00” thick, depending on the material.

Q: How precise is your laser cutting?

Typical tolerances are ±0.010" for part size and ±0.005" to ±0.010" for holes, depending on material thickness.